Chocolate Transfer Pump

Chocolate transfer pumps are an essential piece of equipment in the chocolate industry

Product description

Description

Chocolate transfer pumps are an essential piece of equipment in the chocolate industry.

They pump chocolate from one vessel to another and can be used to create Chocolate designs.

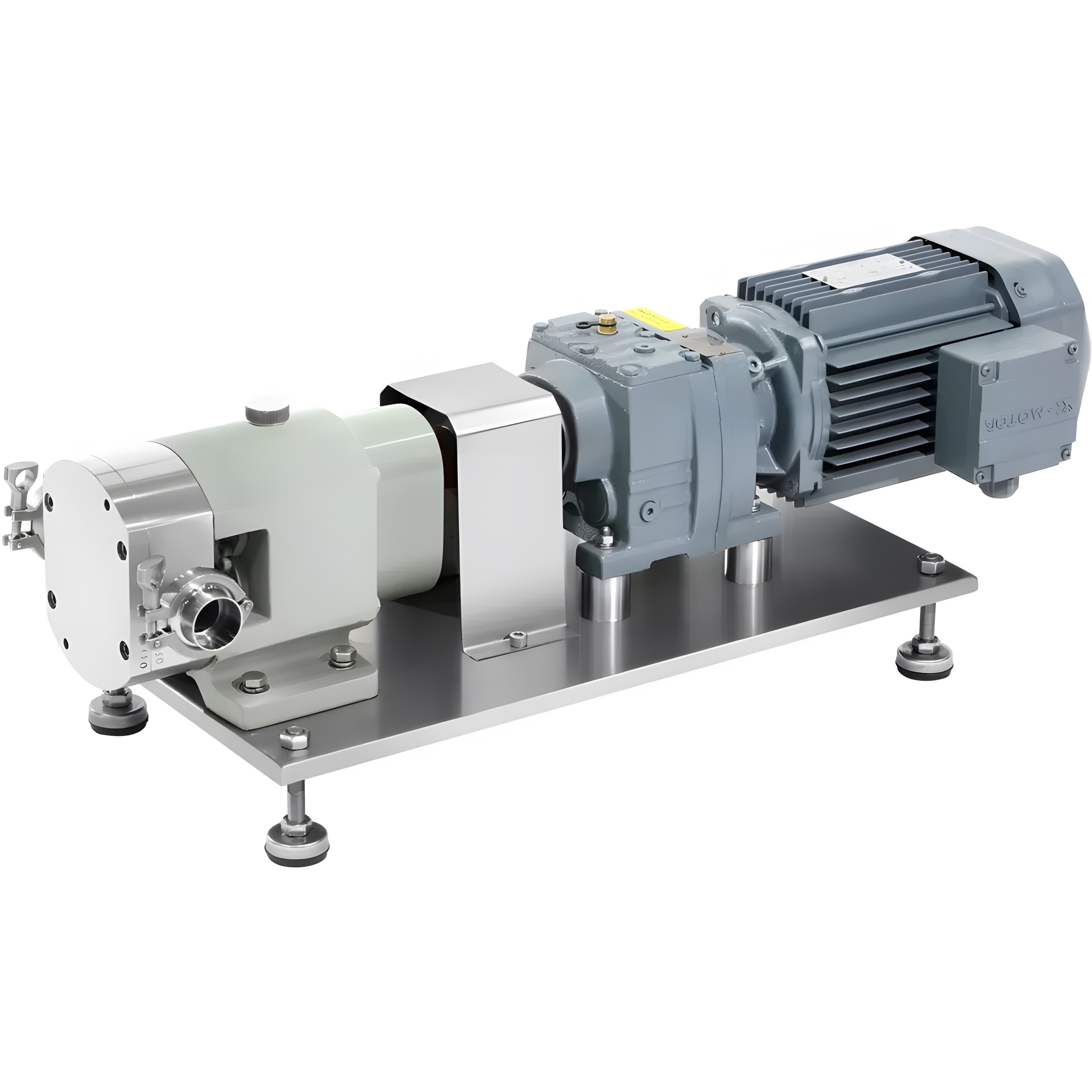

Chocolate transfer pumps come in various sizes and shapes and can be made from multiple materials. The most common material for chocolate transfer pumps is stainless steel, which is resistant to corrosion and easy to clean.

A chocolate transfer pump with a jacket is specially designed for quickly transferring solidified material. The jacketed cavity surrounding the rotor chamber can be circulated with a hot medium such as hot water or steam, either heating the cavity of rotors and maintaining consistent temperature delivery of the materials according to specific requirements.

Product Feature For Stainless Steel Lobe Pump :

1. Rotary Lobe Pump is a rotary positive displacement pump with high efficiency and long life.

2. The body is with a water-circulating heat preservation system.

3. Customers can choose a different model according to the flow rate required

4. The chocolate mass pump can be used individually or with another production line for automatic chocolate mass feeding.

Product advantages

Hygienic standard: All parts in contact with the medium (material) are made of stainless steel (SUS304, AISL316, 316L), in line with sanitary standards.

Working efficiency: up to 90%

medium transmission: it can transport high viscosity medium up to 1.5 million CPS, AS AS AS sensitive medium, containing solid soft particle media, up to 60%.

Reversible operation: using the pump's symmetrical structure, reversible conveying direction, forward suction, and reverse flushing.

Seal: Provides many types of sealing options; optional double-sided mechanical seal design, suitable for dry running.

Positioning structure: unique rotor installation design, accurate positioning, easy

maintenance. Maintenance: compact structure, small footprint, no need to move the pipeline system during maintenance.

Wear-resistant: all contacts The parts are made of stainless steel with almost no wearing parts.

Low-speed operation: low working speed, a particular gap between the rotor and the pump body, no friction, low noise, long service life.

Low cost: high work efficiency, low consumption, environmental protection, less maintenance, and long life.

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!