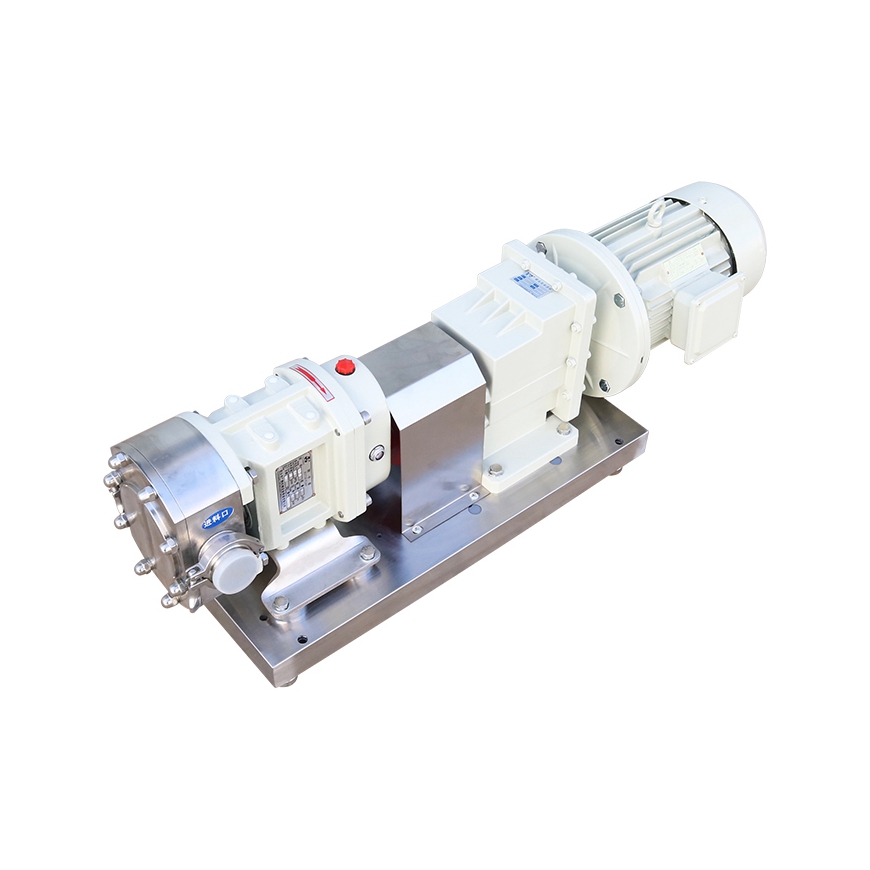

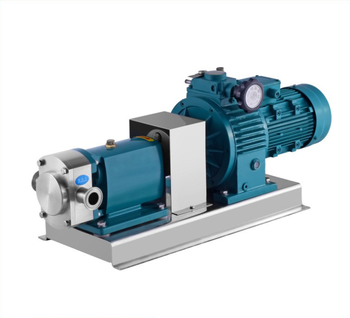

Sanitary Rotary Lobe Pump

Sanitary Rotary Lobe Pump is a positive-displacement pump that consists of vanes mounted to a rotor that rotates inside of a cavity

Product description

Video

Description

Sanitary Rotary Lobe Pump is a positive-displacement pump that consists of vanes mounted to a rotor that rotates inside of a cavity.

Sanitary Rotary Lobe Pump are used in a variety of industries including pulp and paper, chemical, food, beverage,pharmaceutical, and biotechnology.They are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance and good clean-in-place and steam-in-place (CIP/SIP) characteristics.

Rotor pumps can handle solids (e.g., cherries and olives), slurries, pastes, and a variety of liquids. If wetted, they offer self-priming performance. A gentle pumping action minimizes product degradation. They also offer continuous and intermittent reversible flows and can operate dry for brief periods of time. Flow is relatively independent of changes in process pressure, too, so output is relatively constant and continuous.

Wenzhou Ace Machinery stainless steel sanitary food grade transfer rotary lobe pumps are widely used in food industry.

Products features

* All parts of the pump in contact with transported materials are made of tainless Steel and meet sanitation standards

* Easy for cleaning. It has good CIP(Clean-in-place)and IP(Steam-in-place)feature

* High efficiency, reliability, corrosion resistance and can transfer liquid with particles and viscosity up to 1,000,000 cps

* Output flow is constant and stable

* All models with mechanical seal flushing

* Different materials for the balance mechanical seals Sic-tungsten abide Sic-sic Tungsten Carbide-tungsten carbide

* Different drives for options: stepless speed reducer, fixed ratio reducer, variable frequency motor, explosion proof motor, etc

Applications

* Daily chemicals

* Chemical Industry

* Pharmacy Industry: Health care products, Pharmaceutical, Vaccine, Biological meal, Pollen, etc;

* Environmental Protection: Mud, Manure, Fertilizer solution, Sewage, Sludge, Toxic agents, etc;

*Construction Industry: Paints, Coatings, Resins, Organic solvents, Indoor/outdoor wall coatings, Water proof coating, Ceramic coating, Paint coating, Ceramic glazing, etc;

* Other: Papermaking, Textile, Plastic, Biochemical, Coal Industry

How does a Lobe Pump work?

There are 2 lobes within the pump casing that rotate in opposite directions without touching each other. The lobes will rotate passed the suction port of the pump casing, when this happens, the volume between the lobes increases, creating a vacuum which draws liquid into the pump casing. As the lobes rotate towards the discharge port, pressure builds up due to the volume between the lobes decreasing. This causes the liquid within the pump casing to flow out of the discharge port, as shown in the image.

Benefits of Using a Lobe Pump

1.The Lobe Pumps that Wenzhou Ace Machinery supply are fully EHEDG compliant and are manufactured from Stainless Steel to ensure the pumps are hygienic.

2.Can be ATEX rated for pumps being used within potentially explosive environments.

3.Lobe Pumps can be fitted into pipework horizontally or vertically, highlighting their versatility. If the pump is fitted within the pipework vertically, the pump can self-drain, which is particularly helpful alongside the SIP & CIP feature of a Lobe Pump.

4. The mechanical seal and lobes of the pump can be completely pulled out from the front of the pump casing which aids in maintenance of a Lobe Pump.

5.Lobe Pumps have accurate flow control ranging, can be fitted with a variety of connection types, heating or cooling jackets, air or spring loaded integral safety valves, as well as the option of Bi-Wing Lobe Design or Quattro Lobe Design. These variations can all be fitted based on the application you wish to use a Lobe Pump for, let us know what you need, and we’ll spec the pump up for you.

How to maintain a Lobe Pump

Regularly checking your Lobe Pump will avoid unnecessary downtime and reduce breakdown costs.

What to check

Is the pump producing excessive noise? This may indicate lobes dragging against the pump casing, as well as wear problems to the pump bearings or gears.

The gearbox oil level, if the oil level has decreased, check over your pump for oil leaks.

The suction and discharge pressure of the pump, ensure that they are at the standard system levels.

If your Lobe Pump is fitted with a Heating or Cooling Jacket, check the temperature is correct.

The pressure and flow of the flushing system, if featured on your pump.

When to change the oil in your Lobe Pump

After 300 hours of operating since the initial commissioning of the pump, the oil should be changed

After the initial oil change, one should be carried out on your pump every 3000 operating hours or every 3 months, whichever comes first.

If your Lobe Pump isn’t used regularly, the oil should be changed every 2000 hours of operating or at least every 3 months.

Options

Mechanical seals: SiC/SiC or TuC/SiC.

Apart from the single mechanical seal, other sealing types are available:

flushed mechanical seal (quench), double mechanical seal, lip seal (FPM or PTFE), gland packing, O-ring.

Gaskets: FPM or PTFE.

Relief valve on the front cover or external by-pass.

Bi-wing lobes.

Heating chamber.

Isolation can.

Vertical support.

Rectangular nozzle.

Various kinds of drives and protections (gearbox drive with optional frequency converter, pulley/mechanical drive speed selector).

Trolley and/or control panel.

Connections: Clamp, SMS, RJT, etc.

PLEASE CONSULT US DIRECTLY IF YOU HAVE SPECIAL REQUIREMENTS!!!

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!