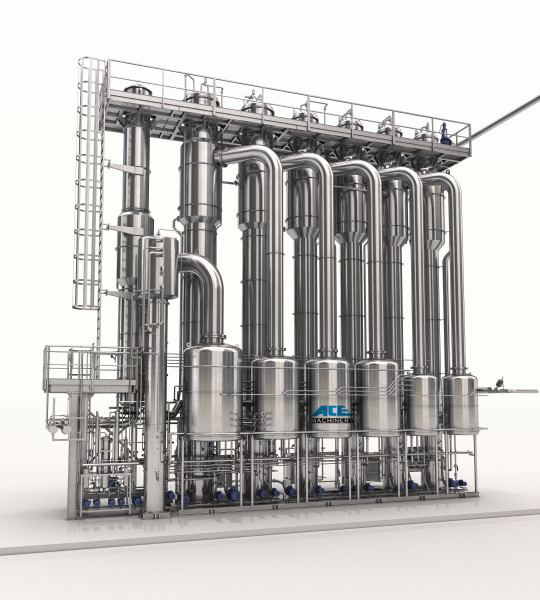

Three Effect Falling Film Evaporator

New Design Good Price Customized Orange Mango Juice Concentration Three Effect Falling Film Evaporator

Product description

Video

Description

A falling film evaporator is a type of evaporator commonly used in the food and beverage industry.

It works by passing a hot fluid (usually steam) over a cold liquid (usual water) flowing down an inclined surface. This causes the fluid to evaporate, and the resulting vapor is condensed and collected.

Falling film evaporators are a type of evaporator commonly used in the food and beverage industry.

Three Effect - or multi-effect falling film evaporator is suitable for low-temperature continuous evaporation and concentration in milk, glucose, starch, xylose, pharmaceutical, chemical, biological engineering, environmental protection engineering, waste liquid recycling, and other industries, with the main characteristics of high heat transfer efficiency and short heating time of materials, so it is especially suitable for heat-sensitive, viscous, foaming and other materials.

System components

Each effect heating evaporator, effect separator, condenser, heat pressure pump, sterilizer, insulation pipe, vacuum system, effect material liquid transfer pump, condensation drainage pump, operation platform, electrical instrumentation control cabinet, and valve, piping, and other system components.

The main characteristics of falling film evaporator

1. The whole equipment plus I heat system has high heat transfer efficiency and short heating time because the steam is heated evenly and the liquid is liquid film type flow evaporation. If configured with a heat pressure pump, it has the advantages of energy-saving and consumption reduction, low steam consumption, and low cooling water circulation.

Two 、Materials evaporate along the inner wall of the tube downward accelerated pressurized flow, adapt to the viscosity of the more significant liquid evaporation concentration.

Three, 、Because the materials evaporate in each tube in the form of film, the heating time of the liquid is short, so it is especially advantageous for food evaporation and concentration, and the nutritional composition of food is preserved to a large extent.

4. The evaporation process under vacuum ensures the sanitary requirements of the materials and the environmental protection requirements and significantly reduces the evaporation temperature. Therefore, it is suitable for the concentration of heat-sensitive materials.

Five 、The equipment is suitable for evaporation and concentration of foaming materials because the material liquid is evaporated in the heating tube in the form of film, that is, the formation of vapor-liquid separation, at the same time, at the bottom of the effect body, most of the material liquid will be pumped away, only a tiny part of the material liquid and all the secondary steam into the separator to strengthen the separation, the whole process of material liquid does not form too significant impact, avoiding the formation of foam.

6. For food evaporation and concentration, the equipment can be equipped with a sterilization function at the same time; the material will be preheated first, then enter the sterilizer, reaching 94 degrees or more, maintain about 24 seconds, that is, enter the first effect body, the material quickly flash, the temperature instantly drops.

7. Equipment can be equipped with a CIP cleaning system to achieve in situ cleaning, the whole set of equipment is easy to operate, with no dead ends.

8. Equipment continuous in and out of material.

9. The equipment can be equipped with an automatic system to realize automatic control of feeding quantity, heating temperature, discharge concentration, and cleaning, and also equipped with protection measures for sensitive materials in case of sudden power failure and malfunction. Other safety, alarm, and other automatic operation and control.

① The evaporated water volume can reach 0.5t/h~100t/h

② The system only uses electricity during regular operation, and the energy consumption of fading each ton of water is 15KW.h to 100KW.h. Its operation cost is 1/8~1/2 of multi-effect evaporation.

③ It is the most energy-saving evaporator, mostly single-effect evaporation, with a slight heating temperature difference and short residence time, which is suitable for heat-sensitive materials.

④ Compact structure, small floor space.

⑤ The equipment is controlled by PLC to realize automatic operation and can run continuously and stably for a long time.

Application:

The ACE falling film effect evaporator has a wide use range:

- For Orange juice/peach juice/grape juice/Pomegranate juice/Tomato paste/apple juice/date juice/mango juice, and any other juice processing;

- For meat slurry/ brewer yeast processing; for fish meal processing;

- For Milk processing: Milk evaporator; Whey evaporator

- For drink usage: tea evaporator; coffee evaporator;

- For wastewater treatment: wastewater evaporator;vinasse evaporator NaCl wastewater treatment

-For pharmaceutical field: TBD OIL concentration; calcium lactate concentration etc

- Any other usage: Amino acid evaporator; chemical evaporator, etc

Characteristics

Vacuum system, fast and low-temperature evaporation; Can be combined with the forced circulation evaporator/crystallizer;

The large scale of concentrate ratio as the products between the different effects can recycle separately, so the concentration ratio can be regulated on large scale;

The equipment is equipped with a CIP cleaning system;

Type : from single effect to 8 effect;

Capacity:0.5-100t/hr

Multi heating source: Steam/ conductive oil/hot water

Save energy;

If you need falling film evaporator, please contact us, 20 years of experience, free technical support.

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!